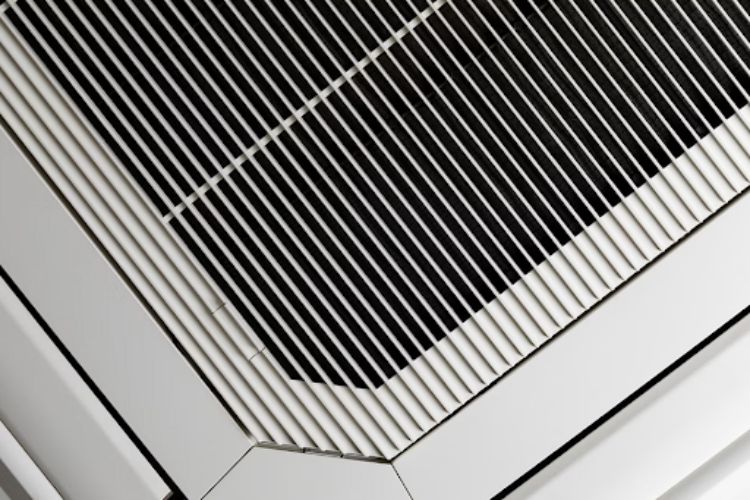

Industrial Air Purifier

Industrial Air Purifier

Industrial air purifiers are essential tools for removing harmful pollutants from the air in commercial and industrial settings. They use advanced filtration systems to capture a variety of airborne particles, such as dust, smoke, pollen, mould spores and other allergens. Industrial air purifiers can also help reduce odours and chemical fumes that can be hazardous to human health. These highly efficient machines provide cleaner indoor air quality for both workers and customers alike.

Benefits of an Industrial Air Purifier

As industrial processes become more complex and involve the use of hazardous materials, air quality can become a serious issue. An industrial air purifier is an invaluable tool for ensuring that your workplace remains safe and healthy for employees and customers alike. In addition to improved air quality, an industrial air purifier offers several other benefits that are essential to businesses today.

Improved Air Quality and Health Benefits: Industrial air purifiers are designed to remove particulates such as dust, smoke, chemicals, fumes, bacteria, mould spores and other airborne contaminants from the workplace environment. This ensures that employees are not exposed to dangerous levels of pollutants while they work. For workers who may be more susceptible to respiratory issues due to existing conditions or allergies, cleaner indoor air means fewer days off due to illness or respiratory distress.

Enhanced Business Productivity and Efficiency: An industrial air purifier can also help improve overall business productivity by creating a healthier working environment for employees.

Types of Industrial Air Purifiers

Industrial air purifiers are a must for any business that needs to protect its employees from airborne contaminants. With so many different types of air purifiers on the market, it can be hard to know which one is best for your business. In this article, we’ll discuss two of the most popular types of industrial air purifiers: HEPA filters and activated carbon filters.

HEPA (High-Efficiency Particulate Air) filters are considered the gold standard in air filtration systems. These filters work by trapping particles as small as 0.3 microns in size, making them ideal for capturing dust, pollen, smoke and other allergens. HEPA filters also feature high airflow rates and low energy consumption levels, making them cost-effective options if you’re looking to clean large areas quickly and efficiently.

Activated carbon filters are another type of filter designed specifically for industrial use. These systems work by absorbing odours and toxic gases such as formaldehyde and benzene from the air using a special type of charcoal material known as “activated carbon.” Activated carbon has a very large surface area which allows it to capture more pollutants than other types of filter media such as foam or paper-based products.

Installation Considerations for An Industrial Air Purifier

Industrial air purifiers are essential components of any facility that needs to protect its workers and visitors from poor air quality. As such, it is important to consider the installation process for an industrial air purifier carefully. To ensure proper installation, there are several considerations you should keep in mind.

First and foremost, the unit must be placed in a location with adequate airflow. The placement of the unit will determine how well it functions. If the airflow is blocked or restricted by other equipment or furniture, then it will not filter as effectively as possible. Additionally, when deciding on a location for your industrial air purifier, make sure that it’s not too close to any heat sources like vents or radiators – this will cause the filter to work harder than necessary and could lead to premature breakdowns and maintenance issues over time.

Another key consideration is electrical compatibility – make sure that you have sufficient power outlets available near your chosen site for powering up your new industrial air purifier along with any other equipment required for its operation (like fans).

Maintenance Requirements for An Industrial Air Purifier

Maintenance Requirements for An Industrial Air Purifier

Industrial air purifiers are essential for keeping the air quality in industrial facilities healthy, safe and clean. Proper maintenance of these devices is necessary to ensure that they continue functioning optimally, and this article will discuss some of the key requirements for maintaining an industrial air purifier.

The first maintenance requirement is to replace filters regularly. Industrial air purifiers come with a variety of filters designed to capture different types of airborne contaminants such as dust, pollen, smoke and other particles. These filters need to be changed according to the manufacturer’s instructions or when they become noticeably dirty or clogged up with particles.

It’s also important to regularly check that all of the components are working properly and make small adjustments if necessary. This includes inspecting hoses and seals for any leaks or damage; checking that fans are running at full speed; ensuring that electrical connections are secure; cleaning fan blades; checking the temperature sensor readings are accurate; making sure all lights on the control panel are in working order; and checking for any blockages in vents or ducts.

Conclusion

Industrial air purifiers are an important tool for businesses and organizations looking to improve their indoor air quality. They can help reduce airborne contaminants, such as dust, smoke, pollen, mould spores and other allergens. Industrial air purifiers also offer greater efficiency than traditional HVAC systems by filtering out smaller particles that could cause health problems. With a variety of models on the market today, there is sure to be an industrial air purifier that can meet your needs and provide clean indoor air for all your employees.