The world of industrial manufacturing is rapidly changing as new technologies are emerging and existing ones are being further developed. Technological advancements such as robotics, artificial intelligence, and 3D printing have allowed for considerable advances in manufacturing industrial goods. As a result of these technological developments, manufacturers can create products quicker than ever before while using fewer resources.

The world of industrial manufacturing is rapidly changing as new technologies are emerging and existing ones are being further developed. Technological advancements such as robotics, artificial intelligence, and 3D printing have allowed for considerable advances in manufacturing industrial goods. As a result of these technological developments, manufacturers can create products quicker than ever before while using fewer resources.

But what does this mean for the future of industrial manufacturing? In this article, we’ll look at some of the latest trends that indicate where the industry is headed and how it can benefit from these innovations – so keep reading to find out.

Table of Contents

What is industrial manufacturing?

Industrial manufacturing is an essential element of modern life, enabling us to use the latest technologies in various industries. From producing drugs and medical supplies to creating smartphones and cars, industrial manufacturing can provide the world with much-needed resources and products. It involves taking individual components, such as metals or plastics, and combining them into larger units using various machines.

This large-scale production often occurs in factories specializing in specific fields of technology or materials science. As industrial manufacturing advances, so too does our access to better tools and services -modernizing societies all over the globe. Check out https://www.morphomfg.com/ for more info.

What is the current state of industrial manufacturing?

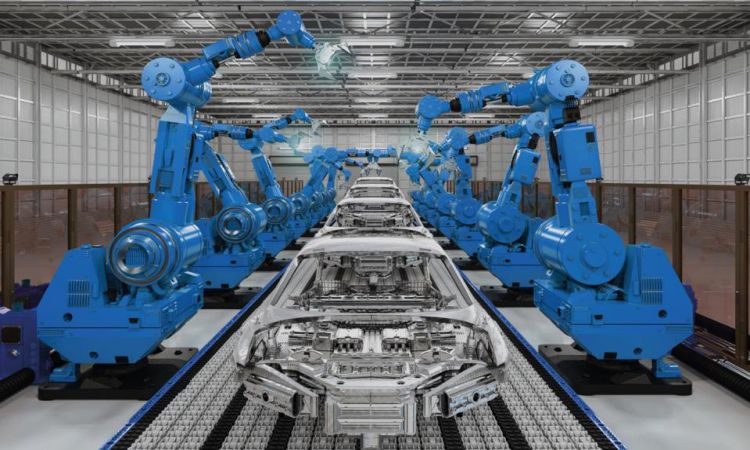

Industrial manufacturing is currently in the midst of a technological revolution. In particular, robotics and 3D printing have been leading the charge when it comes to changing the landscape of this field. Robotics has enabled manufacturers to automate processes once done manually, cutting down on labor costs and production time. Likewise, 3D printing has made it possible for complex parts and components to be created quickly and with minimal waste – something that was not possible before its introduction into factories.

Furthermore, advances in artificial intelligence (AI) are allowing for more efficient decision-making in factory operations. AI can analyze data from all manufacturing areas to identify potential problems or opportunities for improvement – something which would otherwise take too much time or resources.

What are some of the innovations to watch in industrial manufacturing?

It’s clear that industrial manufacturing is changing rapidly, and there are many future innovations to watch out for.

One such innovation that has been making waves in the industry is additive manufacturing (AM). This process uses 3D printing to create parts and components from various materials, including metal and plastic. Combining 3D printing with traditional manufacturing methods makes it possible to produce complex parts quickly and cost-effectively – something which was not possible before AM came along. Furthermore, AM can help reduce lead times by eliminating the need to wait for parts or components from outside sources.

Another area of innovation to consider is virtual reality (VR). VR has already proven successful in the automotive industry, where it can be used to design and test new components. In the near future, VR will likely be used more widely in industrial manufacturing to help streamline production planning and quality assurance processes.

Finally, cloud computing is becoming increasingly important for industrial manufacturers, enabling them to store data securely while making this information accessible anywhere in the world. Cloud-based solutions are being used to manage operations remotely, with companies able to monitor their factories and products all over the globe – a great way to stay on top of things without having to visit each site physically.

How can these innovations benefit the industry?

The innovations discussed above can have a multitude of benefits for the industrial manufacturing industry. For example, additive manufacturing can reduce lead time and cost while improving product quality. Likewise, virtual reality can be used to design components more quickly and accurately, which can help speed up production times or enable manufacturers to create products tailored to specific customer needs.

Meanwhile, cloud computing is great for streamlining operations and enhancing department collaboration. With this technology, companies can access data from around the world in real time, making decisions on the fly with minimal disruption.

Overall, these technological advances are transforming the way industrial manufacturers do business -making it easier to stay ahead of their competitors and remain profitable in the long run.

Tips on how to make the most out of these developments

One of the best ways to make the most out of these new technologies is to ensure that they are implemented in a way that best meets your company’s needs. Each manufacturer will have unique requirements, so understanding these is essential before investing in any new solutions is essential.

Investing in training and education for staff using these innovations is also essential. It will help them get up-to-speed quickly and ensure that everyone understands how the technology works – which is essential for successful implementation.

Finally, consider partnering with a reliable provider when deploying these innovations. A top provider can offer guidance and support every step of the way, ensuring that your transition to the new technology is as smooth as possible.

By taking these steps, industrial manufacturers can make the most out of their investments in new technologies and reap the rewards they have to offer. With careful planning and foresight, staying ahead of the competition and remaining profitable for years is possible.

Conclusion

The industrial manufacturing industry is transforming with the introduction of various new technologies. From additive manufacturing to virtual reality and cloud computing, these innovations can significantly impact businesses operating in this sector – providing them with greater control over their operations while also helping them reduce costs and production times.